[rev_slider alias=”services-1″ slidertitle=”Services – Apr 2021″][/rev_slider]

Our Services

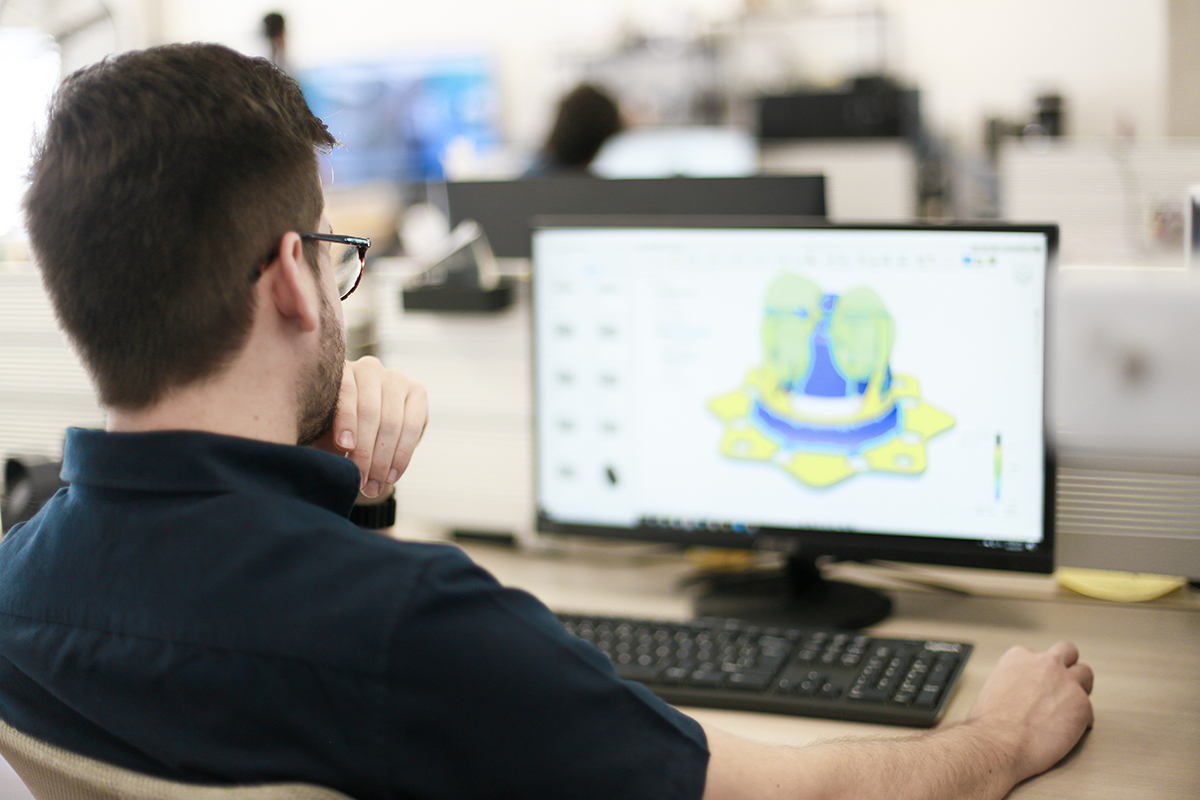

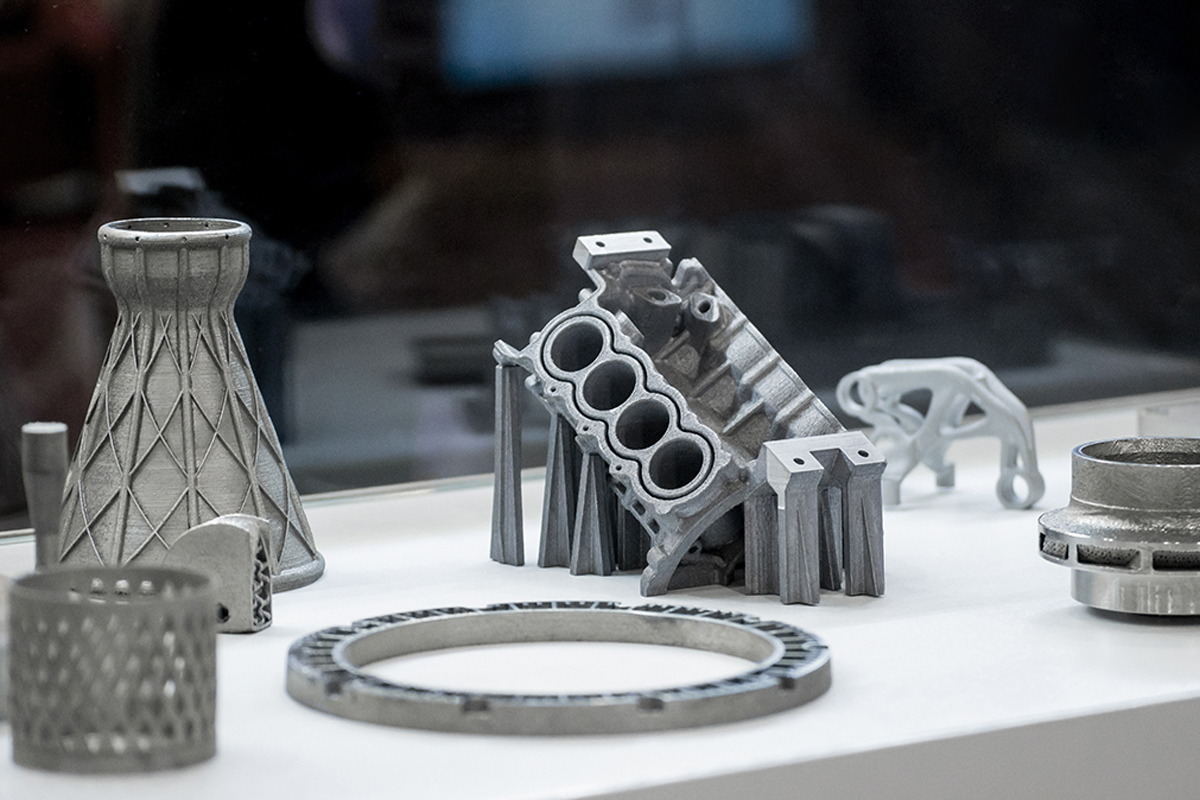

Analyze Inventory and Identify Parts

We utilize business intelligence technologies to analyze inventories and identify parts. Find out how your business can benefit from on-demand manufacturing.

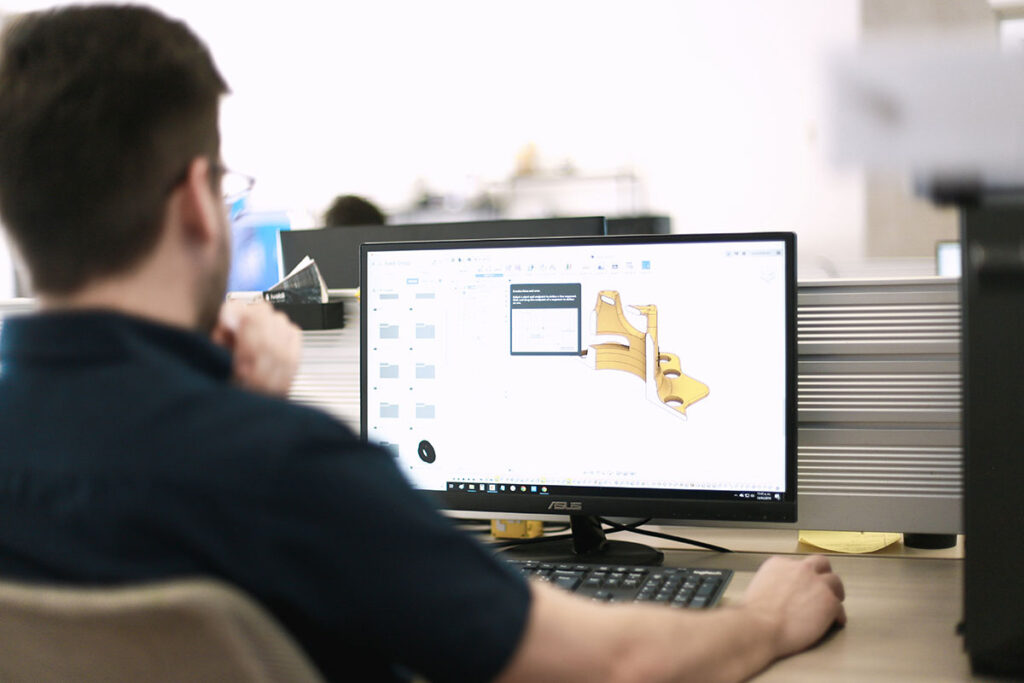

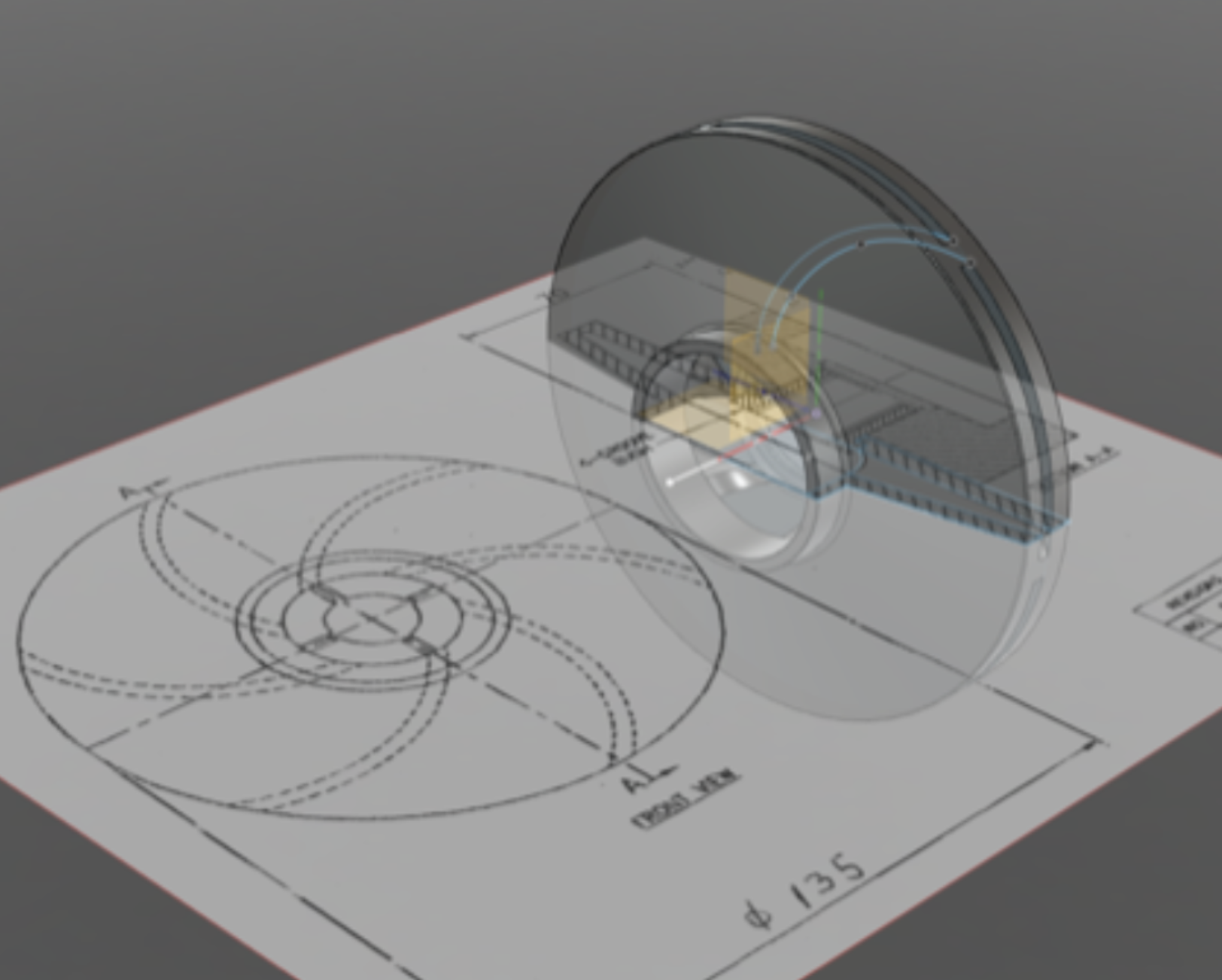

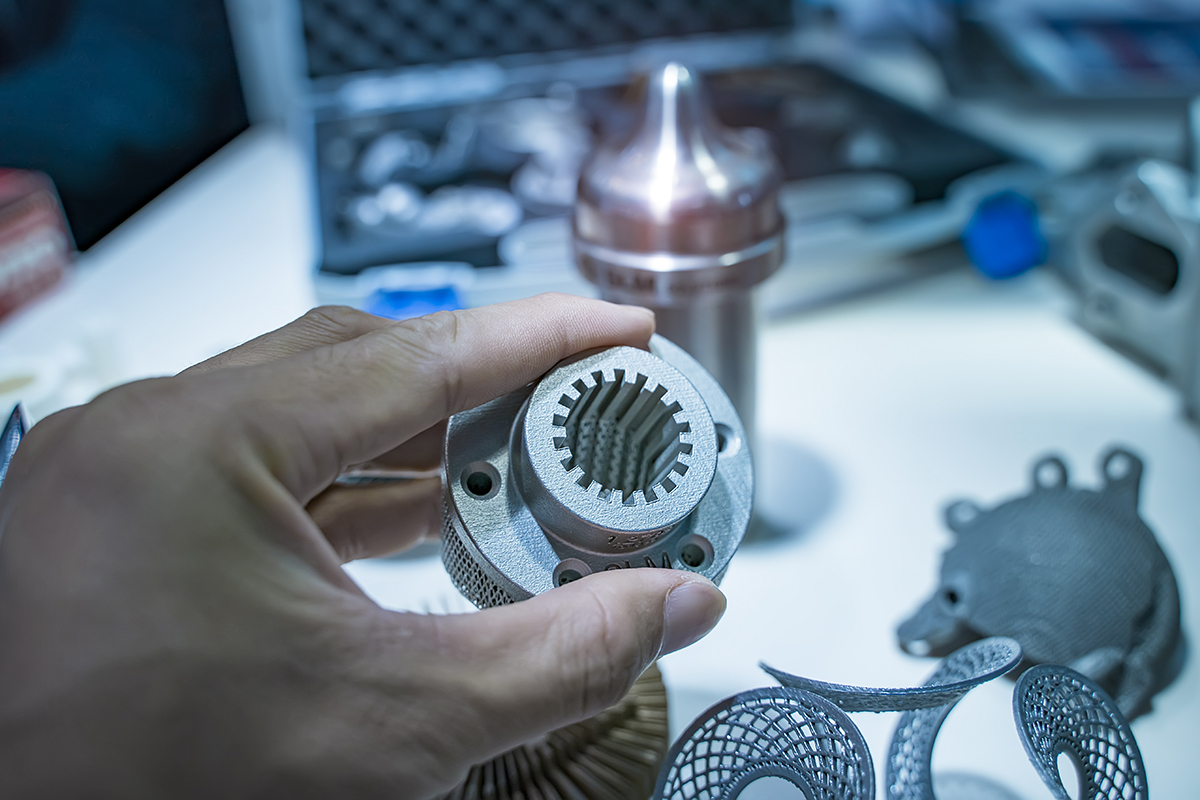

Digitize and Certify Parts

We complement our customers’ industry knowledge with on-demand manufacturing expertise. Find out how Ivaldi can digitize and certify your parts.

Digital Warehouse

Instead of storing physical goods, transform your warehouse into a digital one. Make your supply chain more cost effective and resilient with Ivaldi.

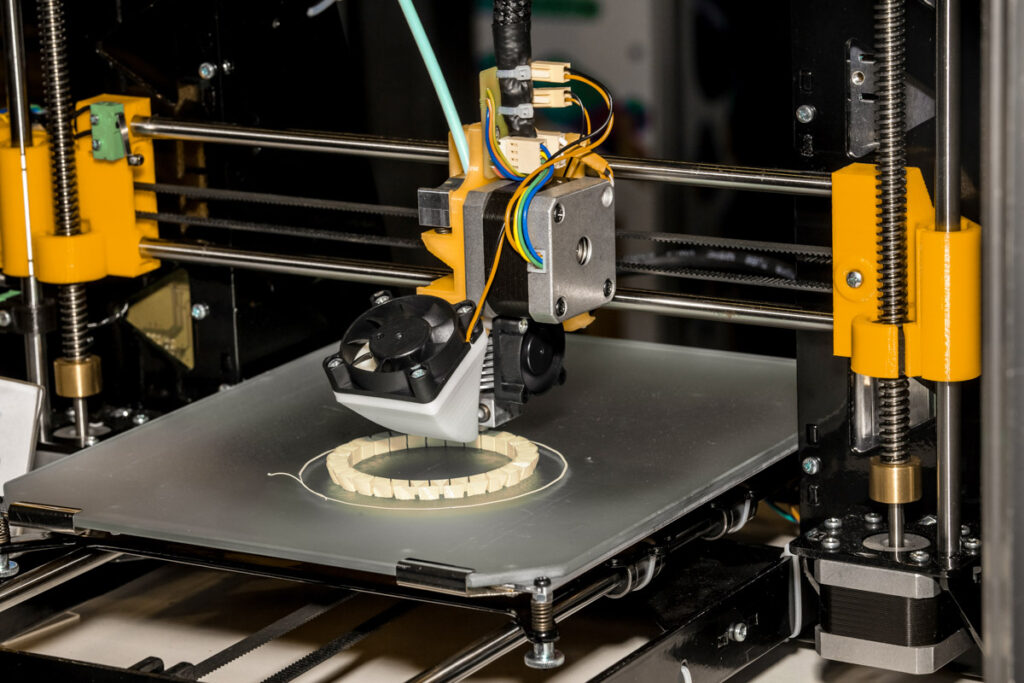

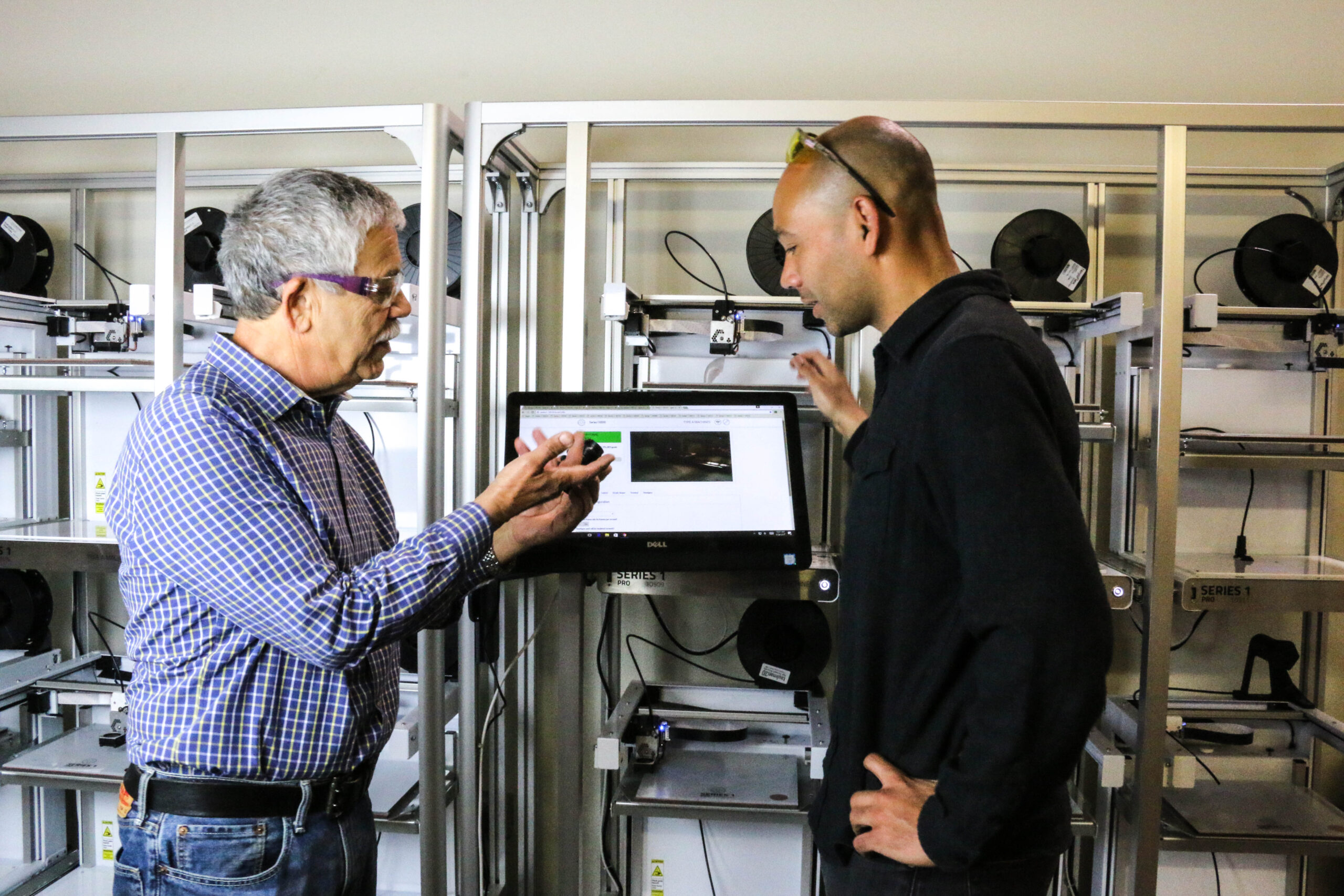

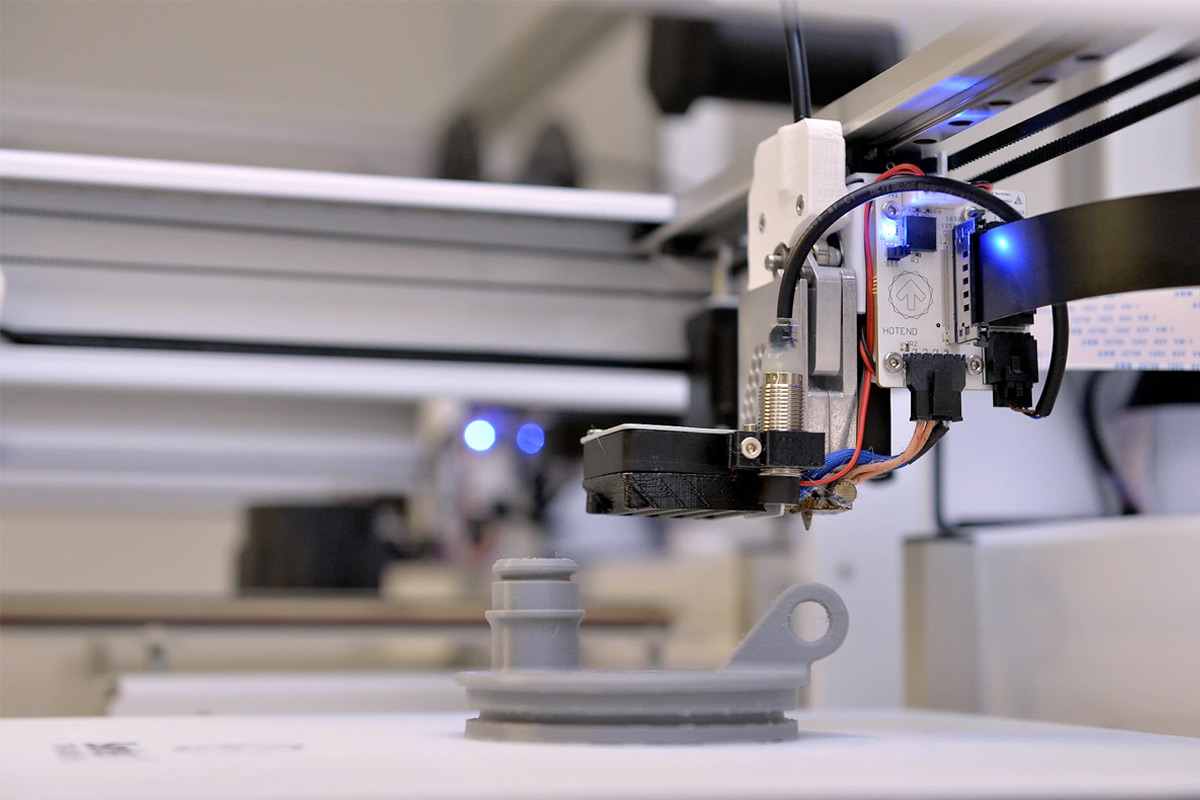

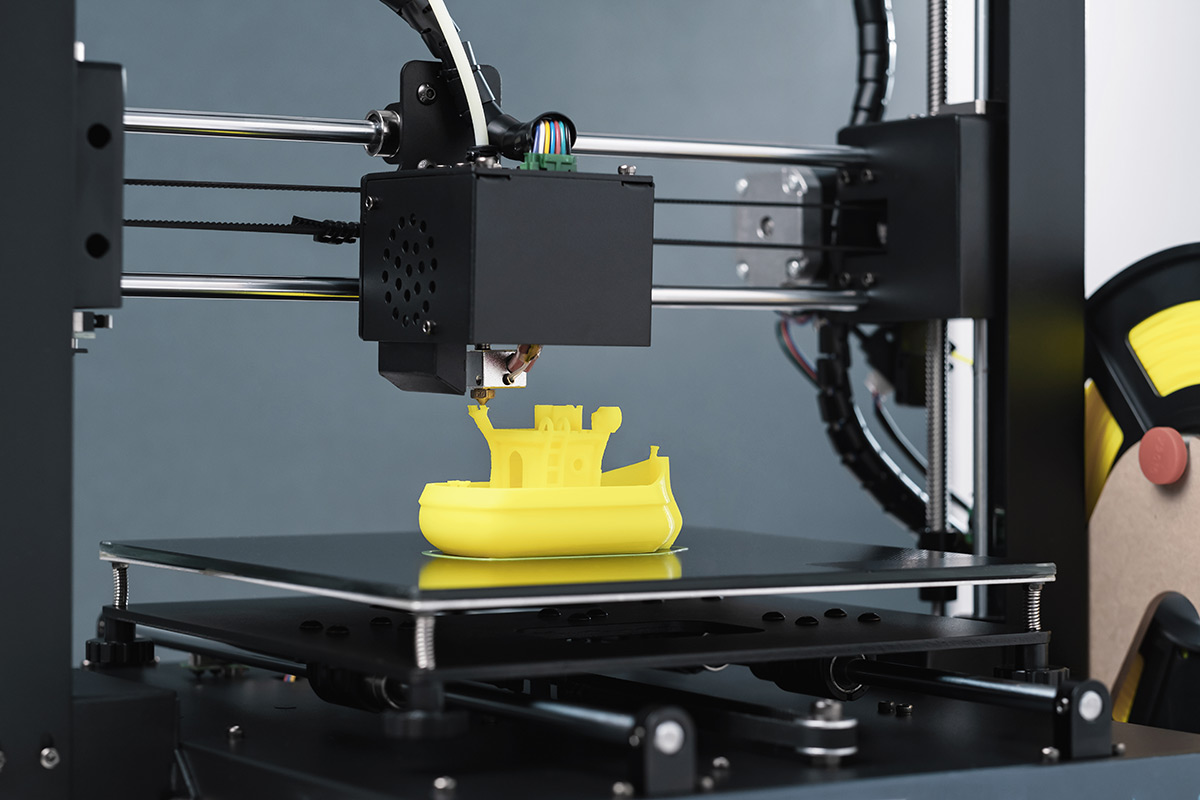

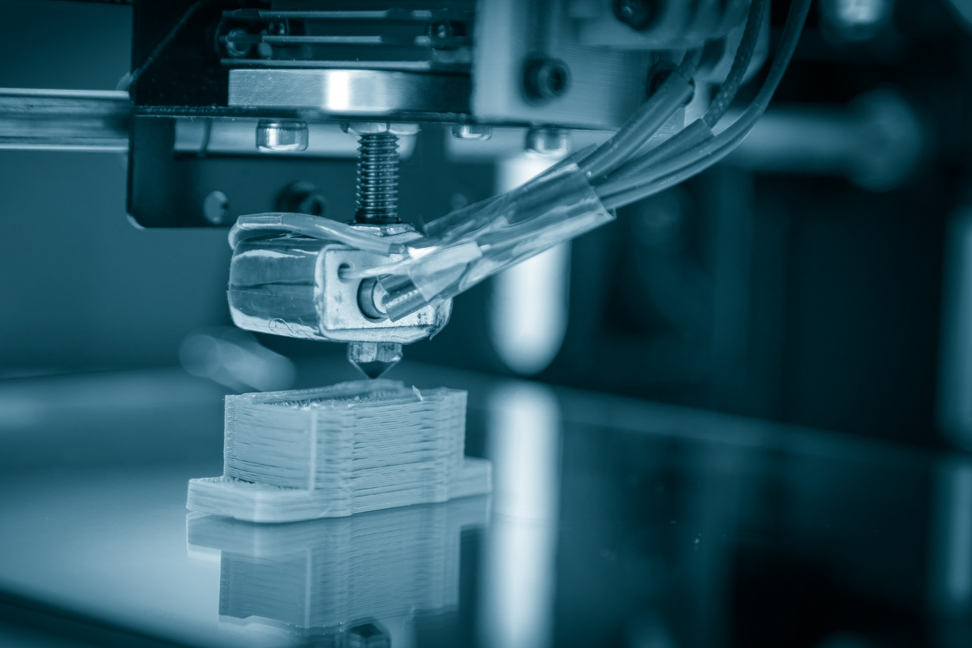

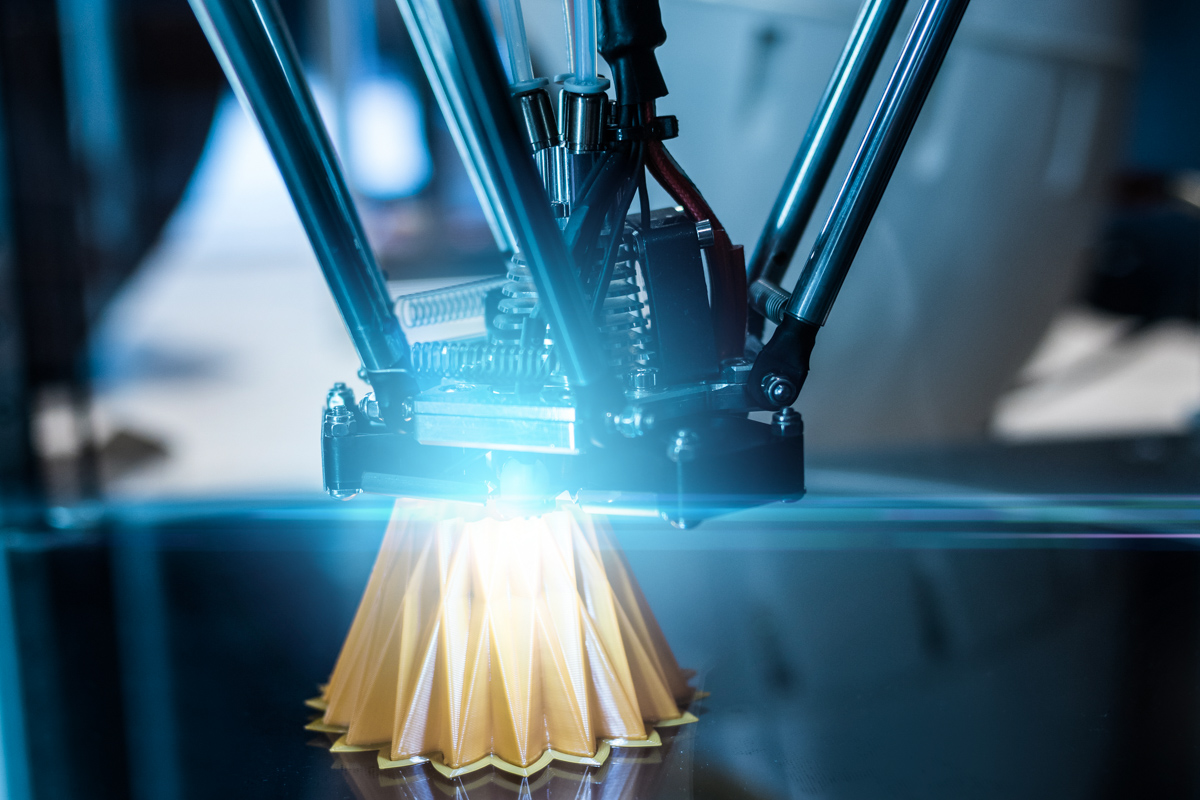

Print on Demand

Our on-demand manufacturing services give you access to a network of certified manufacturers in your needed location. We can also help you setup and certify your own on-demand facilities.

I want to create a more efficient workflow. Which product offering is right for me?

Our product offerings are designed to build on one another. Starting with screening of your data to get a general idea of the possibilities and savings. We then conduct a deep analysis of the data and work with your team to determine how to reduce waste and where to implement Ivaldi’s solutions. In order to accurately assess the best fit for you, contact our sales team.

Do we set size limits for AM and how do we factor that into the cost calculator?

Limits are set based on the specific machines included in our databases. This is ever changing as we onboard new manufacturing partners.

What have we developed that helps to understand the entire product lifecycle not only from a cost perspective but also an emissions and social perspective (carbon calculator with TCO and local impact)

We are constantly developing our software. While many features are under development, they all start as stand alone tools which are tested by our qualified engineering and design team. Currently datasets for AM are missing in available LCA software, so we built our own based on experience and available data.

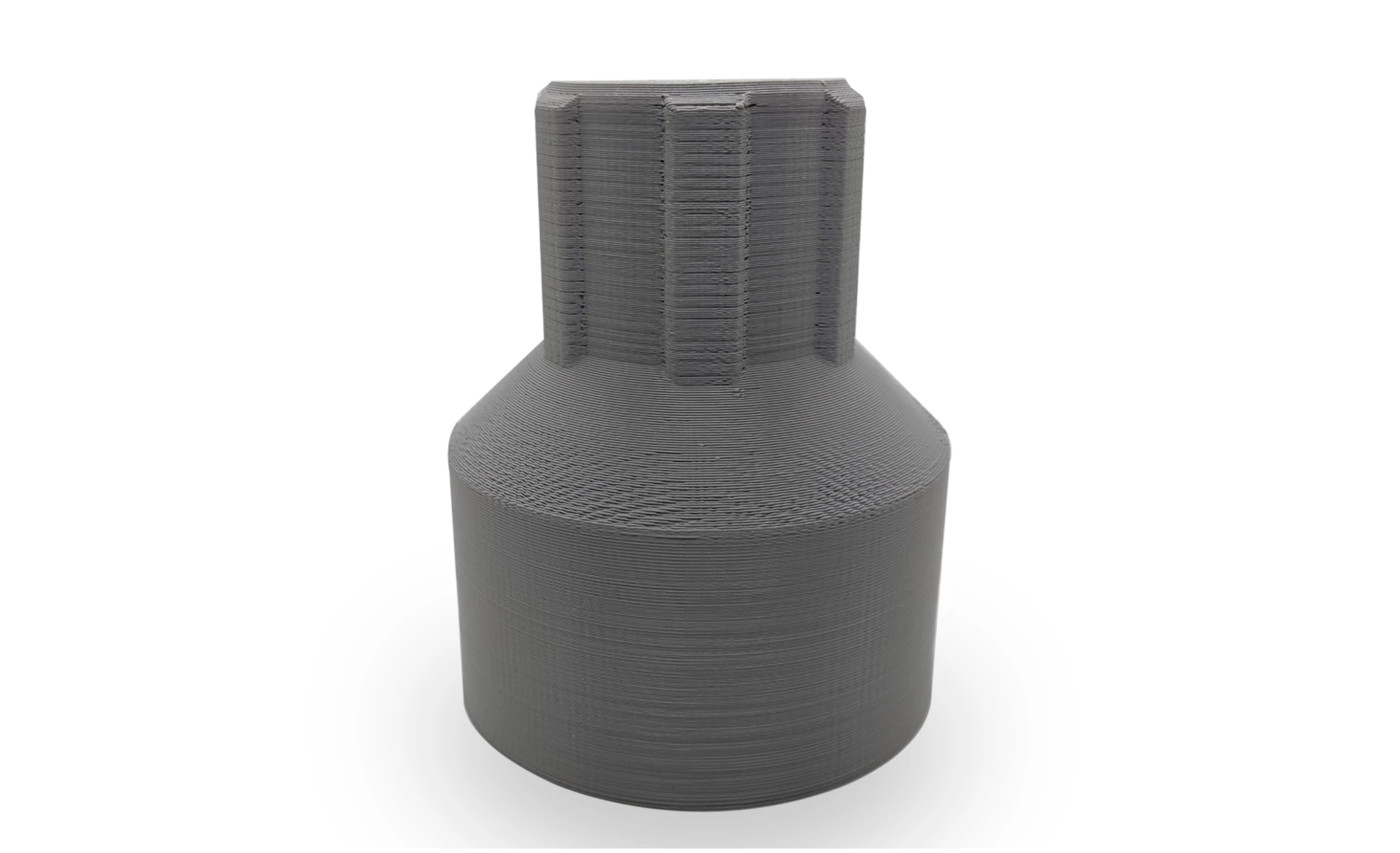

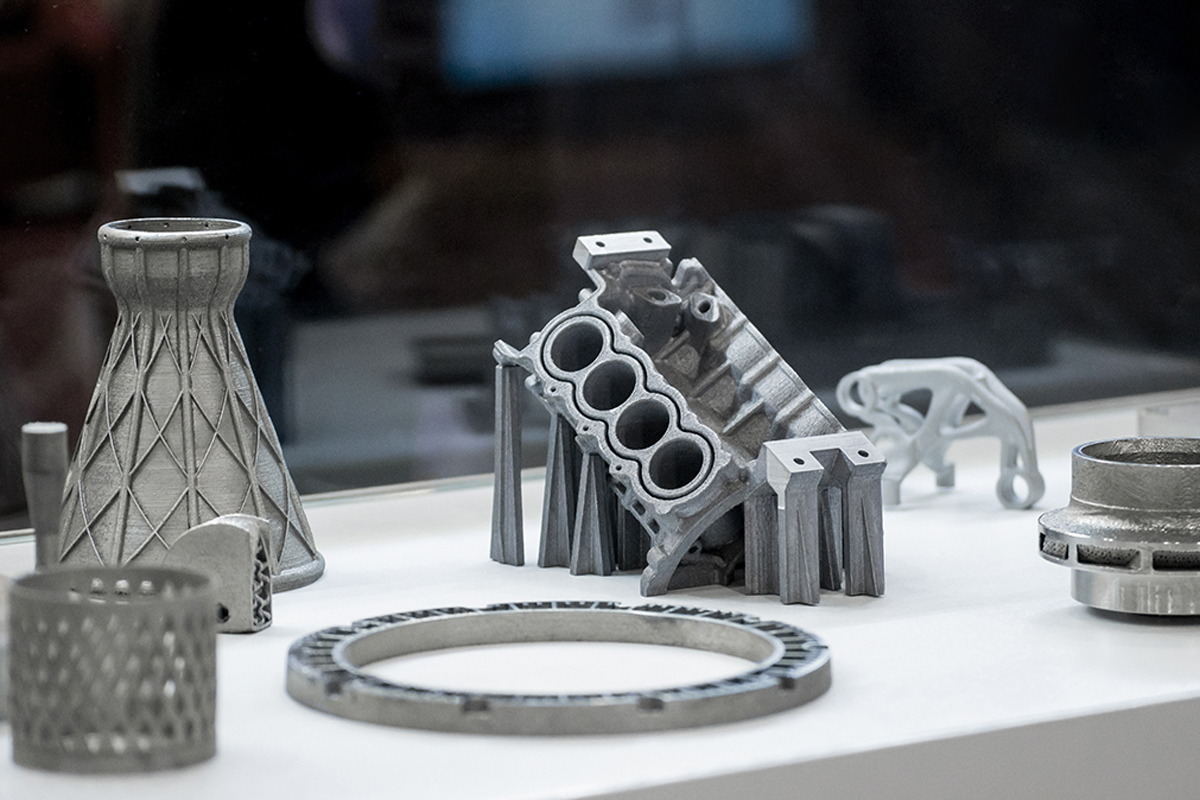

Are there any shape limitations in terms of what geometries the printers can print?

Overhangs are typically possible up to 45º. Anything above that, requires support material. Sizes are limited by printer volume. We can manufacture bigger parts by gluing or welding parts together.

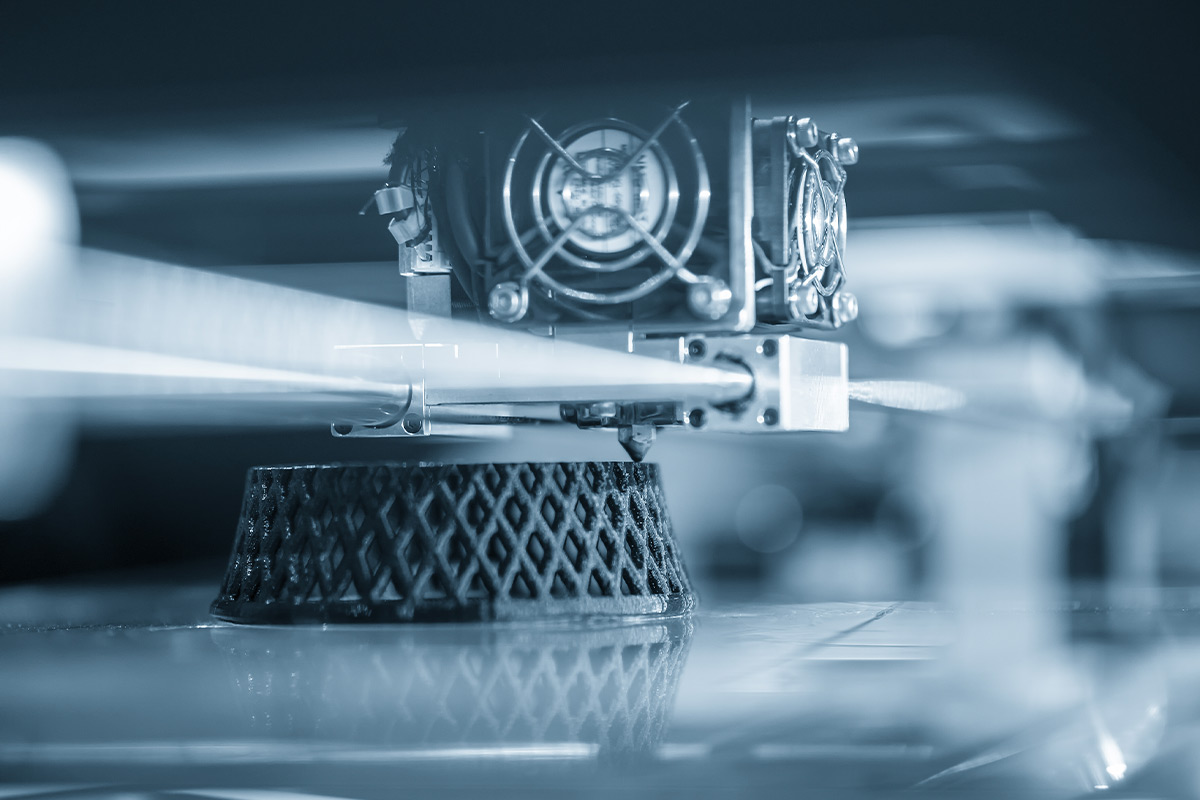

How does resolution affect print time?

The higher the resolution, the more print time. The calculations are associated with travel time on the printhead plus the number of layers for FDM and SLA.

Is post processing necessary? When does this have to be done?

For plastic parts that have overhangs and therefore need support material, post processing is necessary. All metal parts must be post processed. SLA parts require a quick wash as a finishing process.

What do we get out of the analysis process? What results/insights?

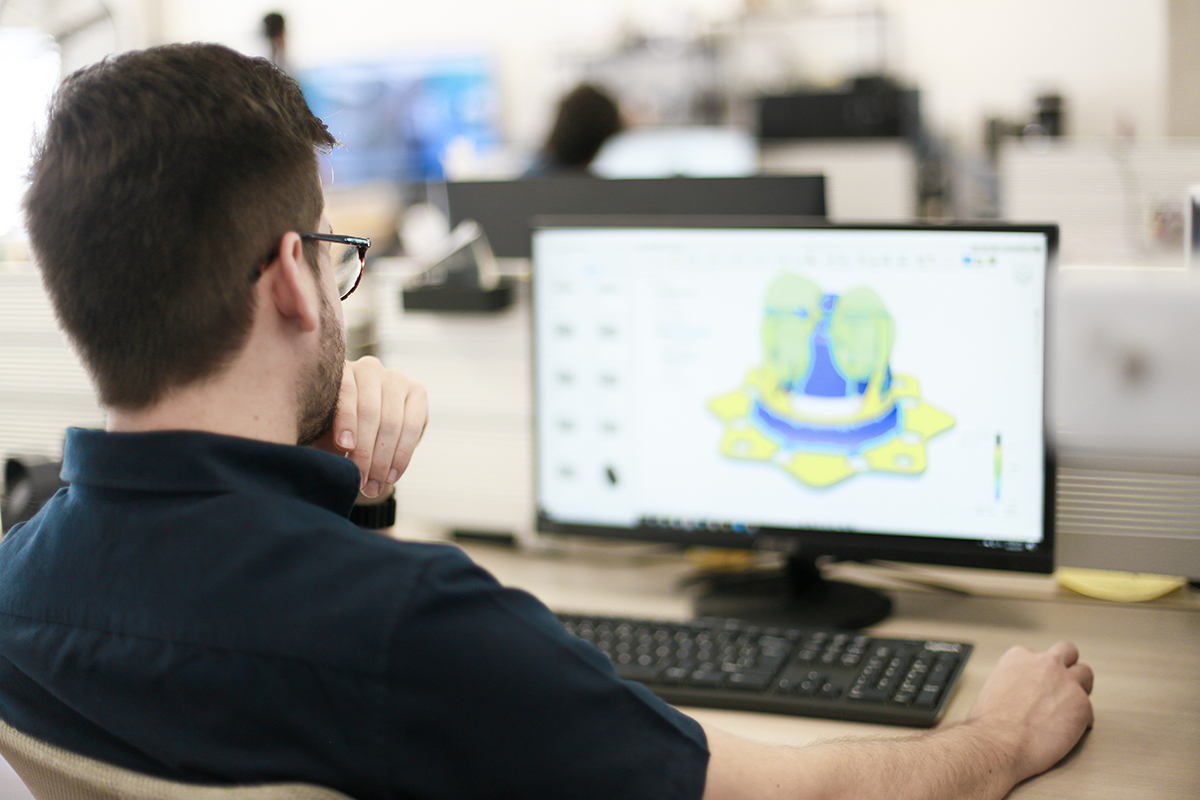

The analysis gives a high level overview of your data. What should be manufactured on demand. The results will be displayed in a dashboard showing the total spent on all products and the total spent on all products within an identified category. Lead time comparison, top candidates based on price, overview of potential CO2 savings. Option for deeper die into the business case for individual parts and further analysis.

Can we try out the software before purchasing a license?

We provide free demos of the software to give potential customers the opportunity to see it in action and ask questions. We also run campaigns at various times of the year where we offer the initial screening free of charge up to a certain amount of data.

What is the plan for implementing new features into the software? When can we see updates/changes?

New features and updates are always in development. We take customer feedback and incorporate it into our product roadmap. Upon request, we can discuss in more details the features that will be made available in the short term.

in the now

Read the latest news

from Ivaldi

October 21, 2021

3D Printing Activities for Offshore Spare Parts

October 17, 2021

Ivaldi Group Featured in E24

October 12, 2021

Espen Sivertsen, CEO Ivaldi Group speaks with Finansavisen

October 5, 2021

Ivaldi Group: Making Spare Parts Logistics more Sustainable and Cost-effective

September 21, 2021

Start-up Spotlight Marketing Week Podcast – Ivaldi

September 4, 2021

Meet the team: Ingvild Sørlie

August 25, 2021

Meet the team: Gro Dyrnes

August 16, 2021

Ivaldi Software Now Available on SAP® Store

August 13, 2021

Announcing a global maritime partnership

July 27, 2021

Meet the team: Miriam Livier

July 22, 2021

Meet the team: Jennifer Hughes

June 30, 2021

Ivaldi in collaboration with DNV develop industry standards for the maritime industry

June 2, 2021

Wilhelmsen and thyssenkrupp Joint Venture (JV) validate Ivaldi Software to identify on-demand manufacturing opportunities for maritime spare parts

May 27, 2021

Ivaldi to take part in the Unconventional Resources Technology Conference 2021

May 27, 2021

Ivaldi Group is working with Anglo American to explore 3D printing technologies to boost supply chain efficiencies and support local businesses

May 27, 2021

Join Ivaldi at Additive Manufacturing (AM) Tech Forum

May 20, 2021

Ivaldi’s CEO will be one of the speakers at the ‘Build Back Better Ports & Marine Technologies to support Exports Seminar’ Event.

May 19, 2021

Ivaldi announces successful test in collaboration with Wilhelmsen and Yinson DH

May 5, 2021

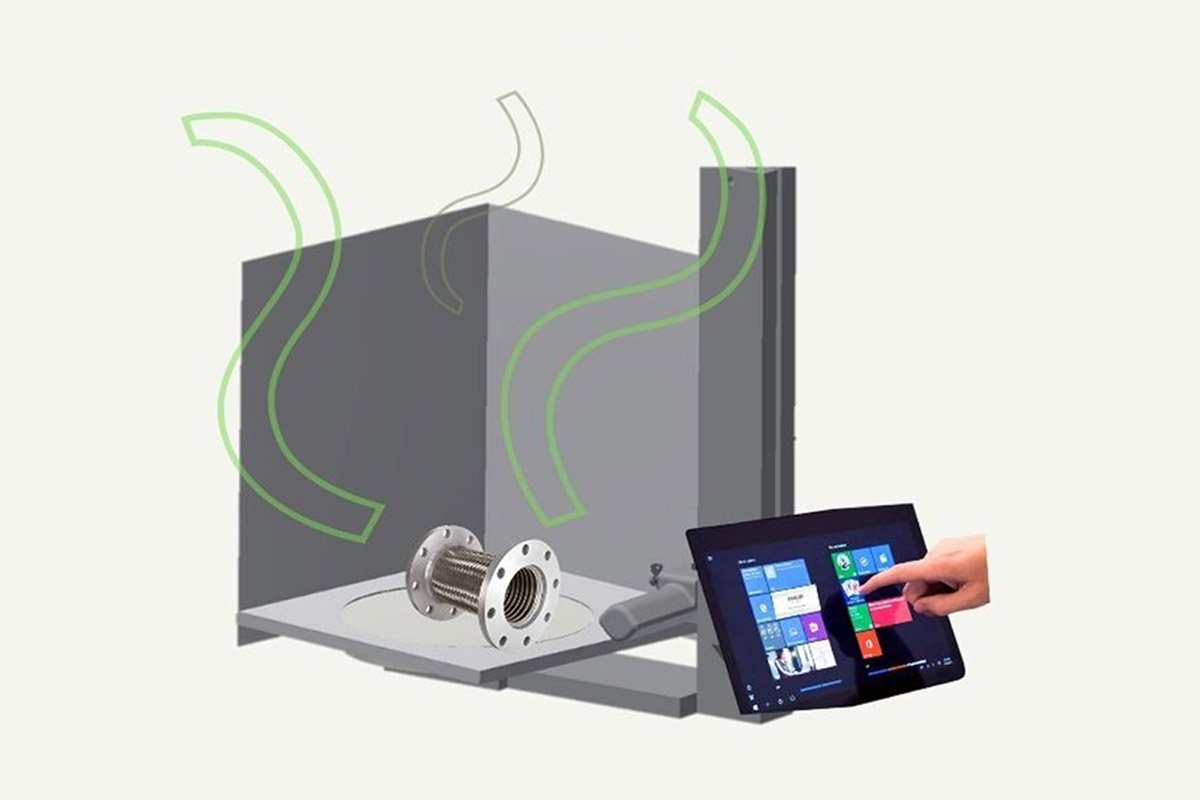

The Wilhelmsen and thyssenkrupp Joint Venture, in collaboration with Ivaldi Group and DNV, digitize, print, test, and deliver a cooling water pipe connector

March 30, 2021

Ivaldi Group participated in the Pivoting Series 2021: Thriving with change

March 30, 2021

#SuezBlocked and the case for re-imagining supply chains

March 22, 2021

Q&A With Ivaldi | SAP.iO Interview Series

March 19, 2021

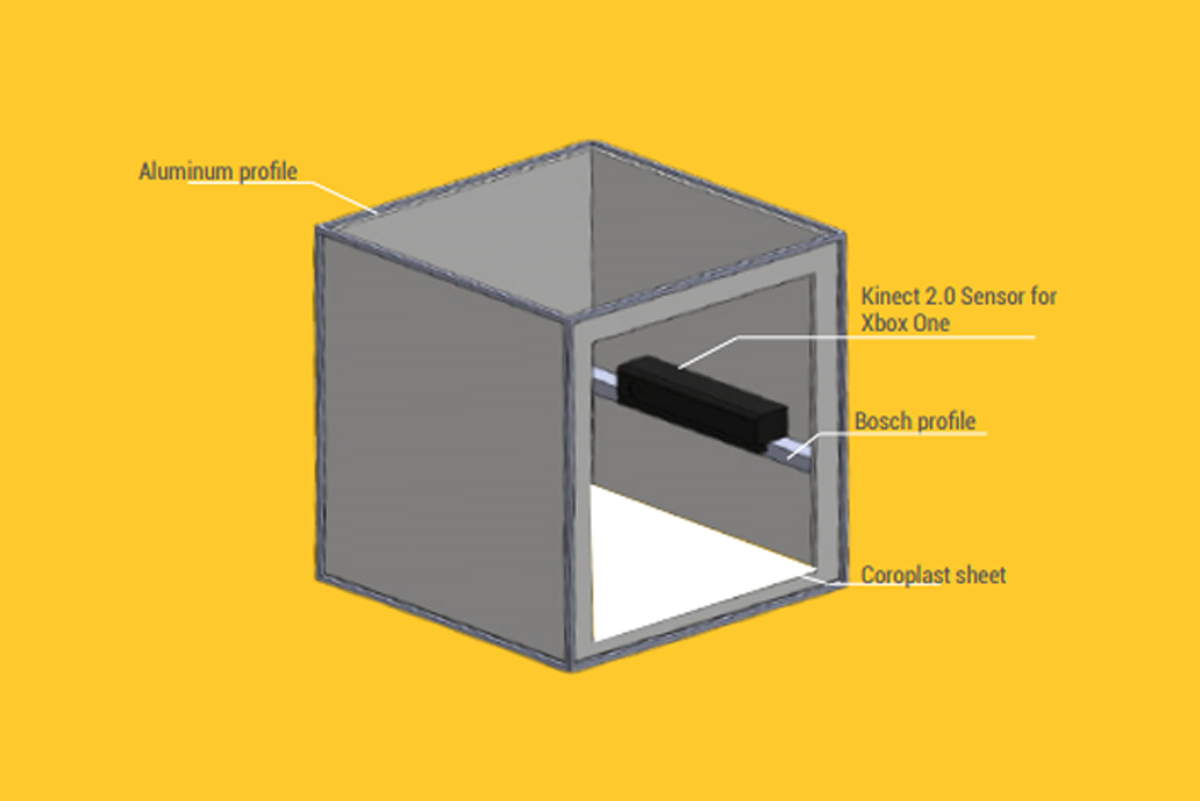

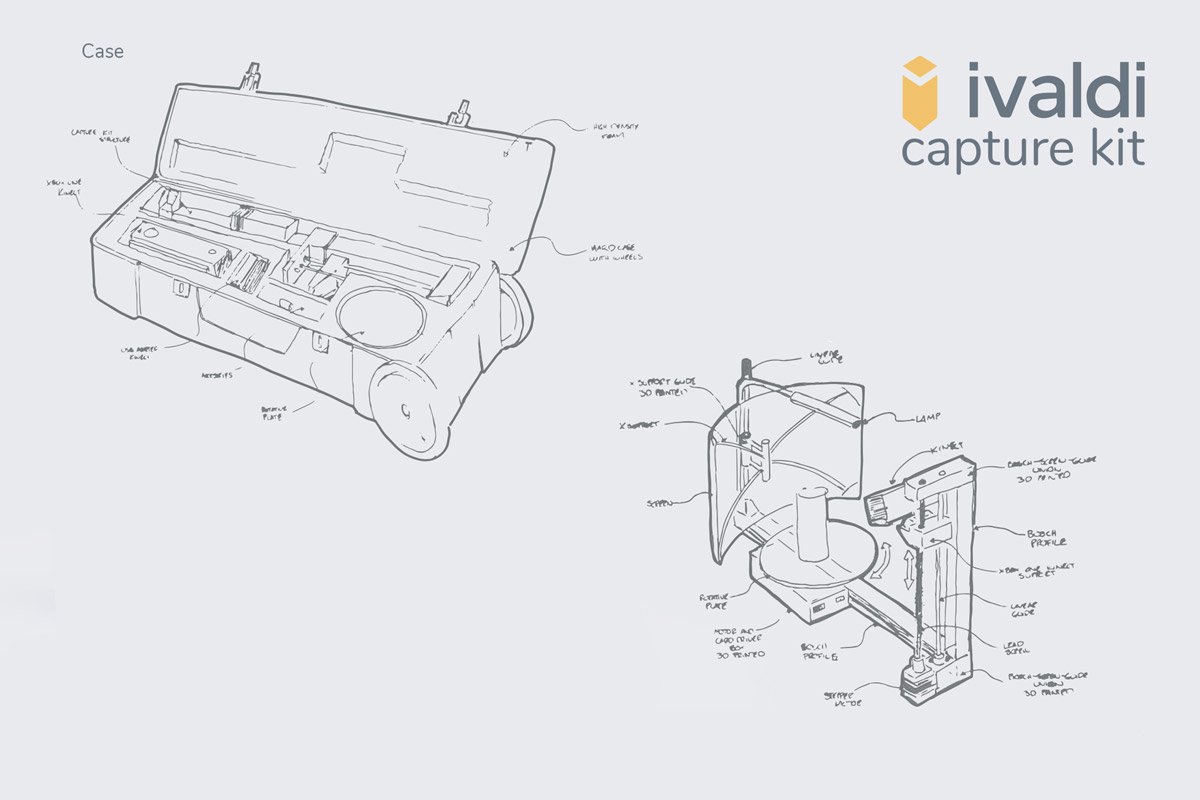

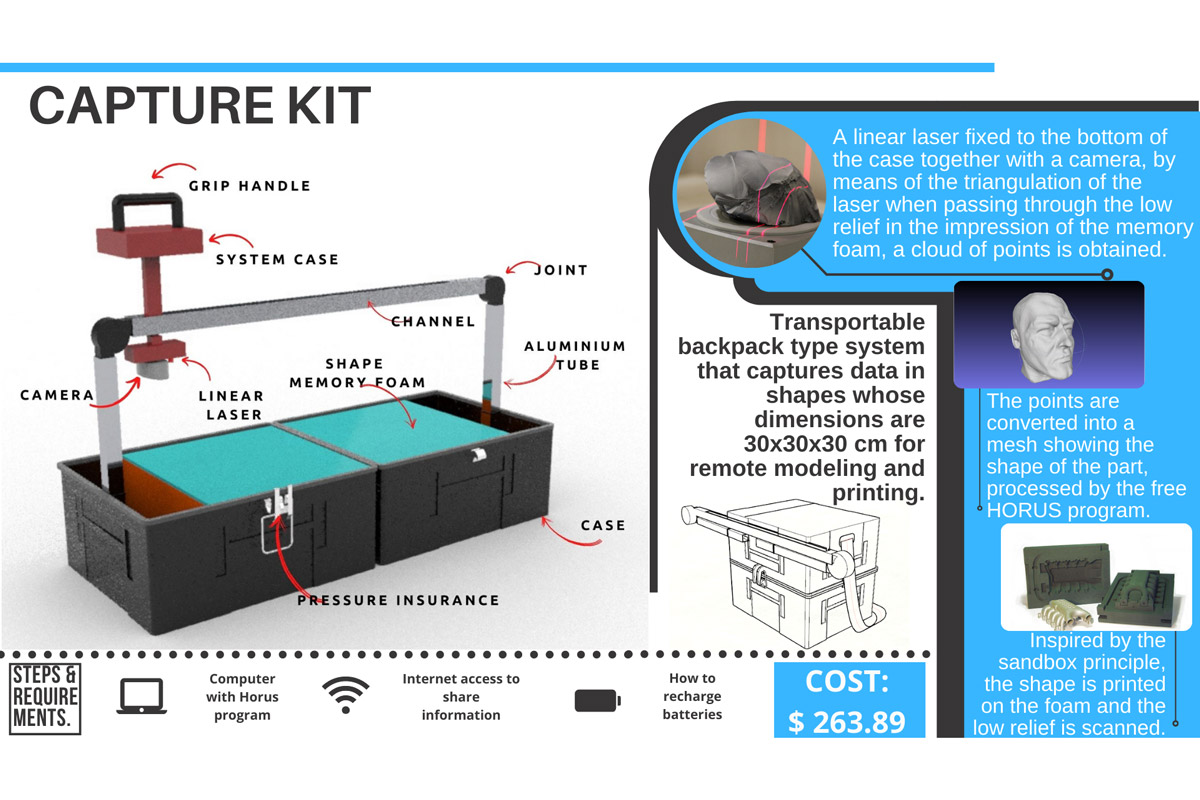

Capture Kit Proposal | Keeping everything simple

March 19, 2021

Creating a capture kit by using the same principle of commercial 3D printers

March 19, 2021

A Capture Kit based on 3 key elements the user, simplicity and quality

March 19, 2021

A Capture Kit inspired by the sandbox principle

February 22, 2021

Spare parts in a pinch: why and how to go digital

February 22, 2021

National Engineer Week Kicks Off

February 21, 2021

Introduction to CAD – Ivaldi Lesson Plan

February 21, 2021

Introduction to On-Demand Manufacturing: A Beginner’s Guide

February 21, 2021

Meet the team: Mary Celestin

January 27, 2021

Ivaldi Participates in SMM DIGITAL’s Speakers’ Corner

January 20, 2021

Ivaldi will be part of SAP.iO North America Foundries’ Demo Days on January 21, 2021

January 18, 2021

Meet the team: Jose Carlos Melendez

January 5, 2021

Why 3D Printing is a Sustainable Solution For Your Business

January 4, 2021

Meet the team: Miguel Diaz

December 28, 2020

Meet the team: Jorge Ponce

December 21, 2020

Meet the team: Anna D’Alessio

December 17, 2020

Meet the team: Aramis Herrera

December 11, 2020

Jennifer Hughes Named Global Key Account Manager at Ivaldi Group

December 10, 2020

IvaIdi Group and FIS join forces to bring Digital Distribution and Additive Manufacturing

December 6, 2020

Meet the team: Joanna Carbajal

November 30, 2020

Ivaldi takes leading role in Phase II Joint Industry Programme (JIP) for Additive Manufacturing of spare parts for Singapore’s Maritime Industry

October 29, 2020

Evolving Cybersecurity in the Industrial Supply Chain

October 28, 2020

Ivaldi Participates in Supply Chain Revolution Podcast, hosted by Sheri Hinish

September 24, 2020

Ivaldi Group to participate in the SAP.iO Foundry New York Fall 2020 virtual accelerator program

August 30, 2020

Made on Demand: Engine Bolt Nut Protector

August 29, 2020

Made on Demand: Gaskets

August 28, 2020

Happy International Women’s Day!

August 27, 2020

Made on Demand: Scupper Plug

August 26, 2020

Ivaldi Mexico

August 25, 2020

Guideline for production-ready parts due in June 2019

August 24, 2020

Wilhelmsen & Ivaldi Group take step towards digitalizing maritime supply chains with 3D printing

August 23, 2020

Providing environmentally friendly solutions for replacement parts

August 22, 2020

Diablo Magazine’s 40 Under 40 Recognizes our VP of Strategy, Nora Toure

August 21, 2020

Towards a guideline for production-ready parts

August 20, 2020

Ivaldi Introduces Part Replacement as a Service

August 19, 2020

Parts on Demand Tools: Digital Capture

August 17, 2020

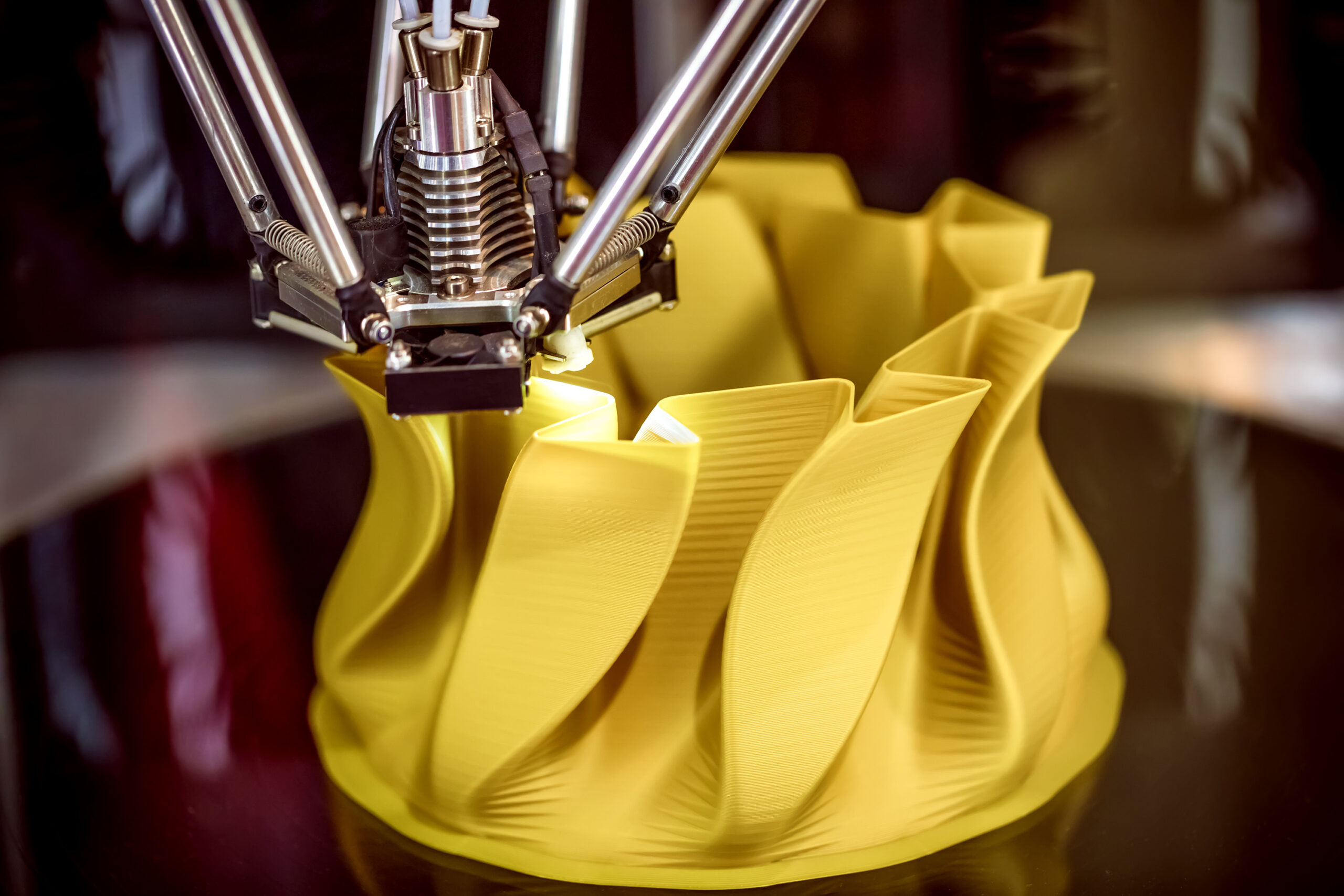

Parts on Demand Tools: Print and Cast

August 16, 2020

Parts on Demand Tools: FDM and SLA

August 15, 2020

2018 Highlights for Ivaldi

August 15, 2020

Live from the Sea

August 14, 2020

Live from the Sea

August 14, 2020

Live from the Sea

August 10, 2020

Ivaldi Group is Now ISO 9001:2015 Certified

August 9, 2020

Ivaldi at Nor-Shipping 2019

August 6, 2020

Additive manufacturing (AM) industry day for oil and gas and maritime industries

August 5, 2020

Henrik O. Madsen joins the Ivaldi Group advisory board

August 4, 2020

Extension of Additive Manufacturing JIPs and deadline for new partners to join JIPs

August 3, 2020

Print my Heart

August 2, 2020

Print my Plane (An Overview of Additive Manufacturing in the Aerospace Industry)

August 1, 2020

Print my Pizza

July 28, 2020

The Use of Textures for Maritime Spare Parts

July 26, 2020

An Eco-Friendly Approach to Shipping Files Not Parts

July 25, 2020

The Future of Manufacturing is Powered by Ivaldi

July 24, 2020

Diablo Magazine’s 40 Under 40 Recognizes our COO, Stefani Pellinen-Chavez

July 23, 2020

Ivaldi’s Technology

Study on Repeatability in Measurements – Human Variability

July 19, 2020

Research on Materials Suitable for the Series 1 Pro

July 18, 2020

An overview of 3D scanners in today’s businesses

July 18, 2020

Live from the Sea

July 17, 2020

Happy Women’s Equality Day

July 16, 2020

Coastal Cleanup Day

July 15, 2020

“Live from the Sea”

July 14, 2020

3D Printing Technologies

July 13, 2020

Additive Manufacturing Allows for Unique Textured Designs

July 12, 2020

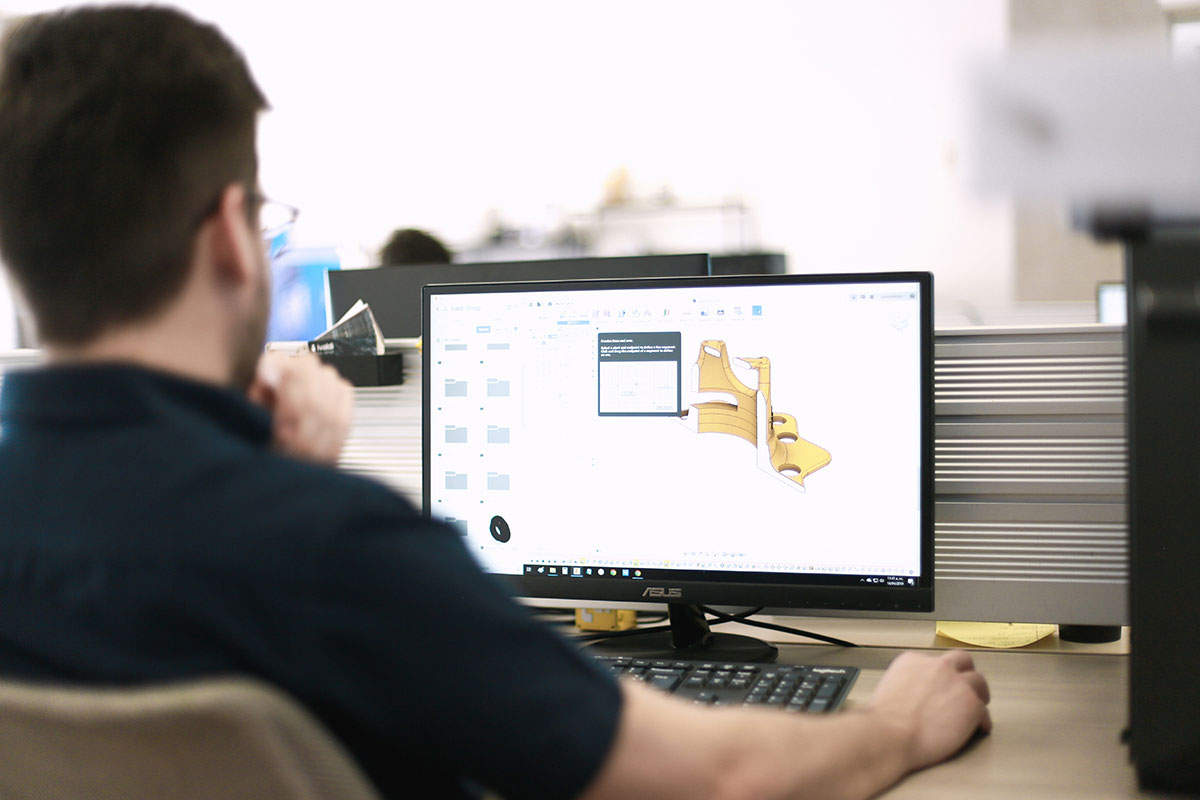

Meet our Engineering Team

July 11, 2020

The Rise of 3D Printed Parts

July 10, 2020

“I learned that in old ships they have many issues with motors, such as gears, pipes, sleeves…”

July 9, 2020

“The lack of spare parts still nails thousands of ships to the port every day”

July 8, 2020

“Wingnuts usually get lost because they’re made out of brass and end up being stolen.”

April 27, 2020

Guideline for production-ready parts due in June 2019

July 7, 2018

Print my Car

May 18, 2017