An Eco-Friendly Approach to Shipping Files Not Parts

Written by Joanna Carbajal

At Ivaldi, we seek to have a positive environmental impact by offering zero inventory solutions, utilizing recyclable material, decreasing material waste and reducing the need for transportation.

By printing on-demand close to the end user, we will be able to achieve zero inventory. By doing so, unsold products will not be wasted.

Recyclable and eco-friendly materials allow for local material recovery and upcycling of old parts.

For example, Filabot has a machine that converts plastic waste into 3D filament. The plastic is grinded, melted and extruded into filament.

Refil makes a recycled filament that, according to their website, has a quality that meets or exceeds premium non-recycled filament. We are currently testing their materials and will be interested to see how it performs. Their ABS filament is made from car dashboards and their PET filament from PET bottles.

Additive manufacturing allows for geometries that cannot be created by another manufacturing process, which reduces material waste. Conventional manufacturing removes material while additive only uses the minimum necessary amount of material. Note that some waste occurs in the form of support material and failed prints, which is why we try to minimize these things. It also costs time and material. With additive manufacturing, environmental and financial incentives are more closely aligned.

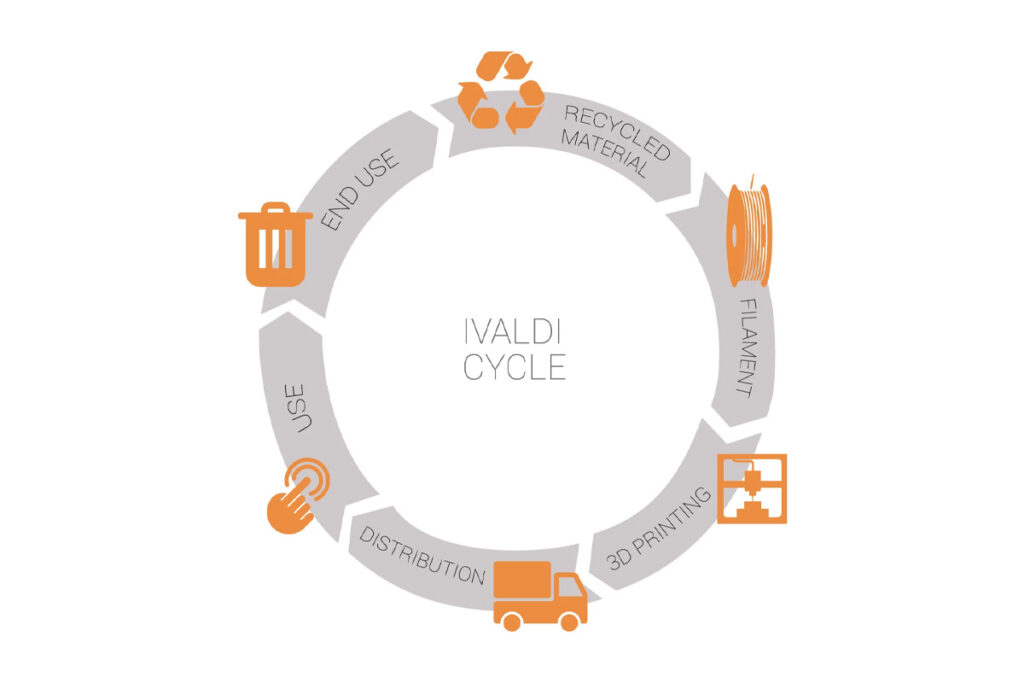

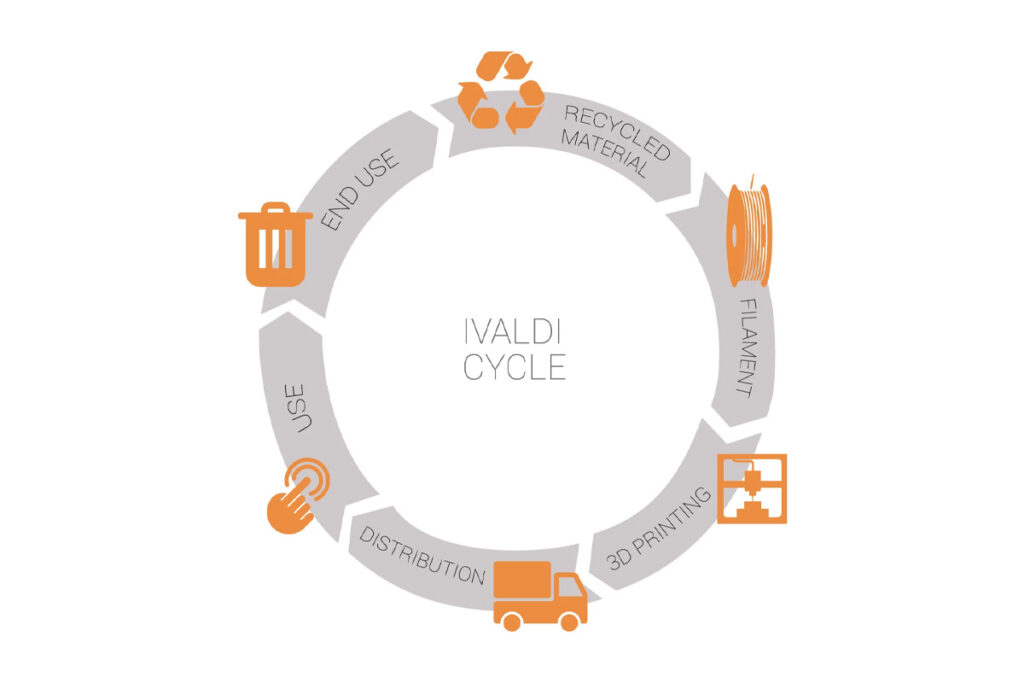

The image above is a visual representation of a general product life-cycle. By bringing manufacturing to the end user, we can reduce or eliminate the distribution stage. This is good for the environment and the cost of the part. We are saving both our customers and society money.

Since we are reducing the need for transportation, it is worth mentioning the consequences involved in transportation.

Pollution – Globally, 33% of CO2 generated from fossil fuels can be attributed to transportation endeavors. Air pollution leads to climate change and impacts air quality. Transportation attributed to 14% of the global greenhouse gas emissions in 2010. 95% of the world’s transportation uses petroleum-based fuels.

Health – Pollutants in the air and water harm animal health. Engines and machinery also cause a lot of noise, which affects the quality of life and can damage hearing.

Damaged Ecosystems and Biodiversity – To increase transportation, infrastructure has to be built. To create more warehouses for inventory, new space has to be created. Changes damage the ecosystem. Animals’ habitats are disrupted and are often driven away.

On-demand prints allow for zero inventory and minimal transportation. We are also helping the environment by using recyclable material. Also, new upgrades that increase fuel efficiency and reduce environmental impact can be brought faster to the market in a more cost-effective way, which lowers barriers to adoption.

We realize that we cannot eliminate plastic, but we are aware that if we use plastic properly, by using reusable and recycled material, we’ll reduce our environmental footprint and also save energy (did you know that 8% of the world’s oil production goes to manufacturing plastics?). Not only are we taking steps into using recycled material, but by having zero inventory, we are eliminating excess unused parts and infrastructure. We are also reducing transportation emissions through in-port production. We are committed to helping the maritime, oil & gas, and offshore industries in a sustainable way.

References:

“Environmental Impacts of Ports”

“Global Greenhouse Gas Emissions”

“How ethical is shipping goods by sea?”

“Moving Toward Eco-Friendly Manufacturing”