3D Printing Technologies

Written by Joanna Carbajal

There are various types of additive manufacturing technologies such as Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Selective Laser Melting (SLM) and Electron Beam Melting (EBM). All of these technologies use a computer-aided design (CAD) file to create a 3D object layer by layer. Examples of printing material can vary from plastic, gold, metal, liquid powder or even chocolate. In this article, we will discuss SLA, SLS, and FDM.

Charles Hull patented SLA in 1986 – making SLA the oldest 3D printing method. SLA uses a light-sensitive liquid resin where a laser traces and solidifies each layer of the 3D model. Once a plastic layer hardens, a platform on the printer drops, allowing the next layer to form. Once the object prints, the objects must be rinsed with a solvent and then placed in an ultraviolet oven to finish processing.

Some of the disadvantages with SLA are that only a limited amount of materials can be used, and it requires post-curing and the usage of support structures. The process and the resin are also expensive.

One of the main advantages of SLA is that once cured, parts are isotropic, meaning they have the same physical properties throughout the entire part. SLA leaves objects smooth and of high resolution. It is perfect for details and thin walls. It also has an excellent surface finish.

The early stages of the “Betsy” – an SLS machine.

Selective Laser Sintering (SLS)

Joe Beaman discovered SLS in the 1980s. SLS and SLA are similar, but SLS uses powdered materials instead of liquids. The powder is heated to temperatures that are below or above the melting point of the used material. The temperature solidifies the powder, bonding the grains of material together in a layer by layer fashion. Before the roller spreads to the next layer of powder, the table lowers, with each successive layer is built on top of the existing layer.

The disadvantages with SLS are that there are no desktop printers due to the complexity and equipment bulk. The printed object has a rough surface finish and requires post-cleanup. Also, the mechanical properties are below those achieved in injection molding.

SLS has several advantages. 1) Objects can be printed in many colors. 2) It is possible to print parts without requiring post-curing. 3) Support structure is not needed. 4) Fabricated prototypes are porous making the part lighter.

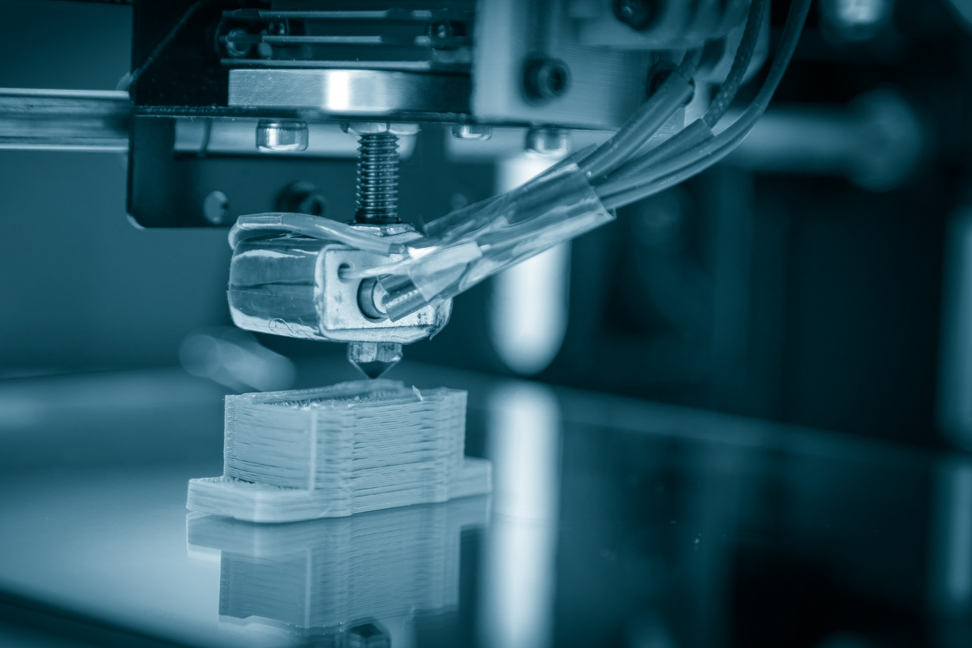

FDM in its early years. Fused Deposition Modeling (FDM) (aka Fused Filament Fabrication or FFF)

FDM in its early years. Fused Deposition Modeling (FDM) (aka Fused Filament Fabrication or FFF)

Scott Crump invented FDM in the 1980’s. However, the 3D printing revolution began until 2005 when patents started expiring. Dr. Adrian Bowyer, as part of the RepRap (self-replicating rapid prototyping) initiative, invented a self-replicating machine called the Darwin 1 in 2008. This machine was capable of producing 60% of the parts required to build itself. Dr. Bowyer made the design of the 3D printer available under an open source/open hardware licenses. Since then, prices have dropped. A $60,000 printer in 2008 might be bought for less than $6,000 today for a similar machine. As patents continue to expire on SLA, SLS, and metal, we expect those prices to lower as well. Such rapid improvement in cost per part is also expected for SLA and SLS.

In FDM, a spool feeds the filament through a heated printer nozzle. The material melts into a semi-liquid state. The print head extrudes the thermoplastic onto the print bed in the x and y directions, depositing material layer by layer in the z-direction.

Some of the limitations of FDM are that it is not good for small details, and it requires surface finishing techniques if a smooth surface is required. Support material is also needed. Although removal is easy, it leaves a rough surface. Also, parts are not isotropic. It is harder to seal if there is a part that needs to hold water.

FDM has various advantages, however. It has an excellent strength to weight ratio. It is also user friendly, economical, functional, and durable. Compared to SLA, FDM uses cleaner, non-harmful materials that are more environmentally friendly. You largely don’t need a production facility or a controlled environment to use FDM, which is why there are desktop printers. FDM also does not require protective equipment to operate.

FDM has more filament options and can print in complex geometries, cavities, and materials. The parts are light yet strong. It is currently the only printing technique that uses production-grade thermoplastics, which allows for objects to have great mechanical, thermal, and chemical qualities. FDM is ideal for prototyping, manufacturing aids and low volume (sub 10,000 units) production volumes. No post curing is needed. When parts are printed with no support material, this makes it possible to get the most cost-effective parts. Due to its excellent versatility, the aerospace, automotive, industrial, commercial, and medical industries use FDM.

Ivaldi Group has taken advantage of FDM technology. We are currently developing maritime spare parts using Type A Machines’ Series 1 Pro. We wanted to make sure that our spare parts were durable and functional rather than aesthetic. FDM allows us to print in complex geometries and cavities. We can print in over 88 different plastic materials without a need for post curing. Due to the expiration of 3D printer patents, a $60,000 printer now costs below $6,000, which allows startups to be able to afford printers. Type A Machines championed this approach with their Print Pod system.

Due to the emerging affordability of additive manufacturing, Ivaldi Group is focusing on massive parallel production technologies. Think of it as “servers” instead of “mainframes.” Instead of having one expensive machine, we can have many machines that total the price of one expensive machine. This enables us to produce parts on demand. With an on-demand logistical pipeline, it is possible for organizations to move towards zero inventory. It’s a radical departure from more traditional “centralized” manufacturing processes, and it is the future of logistics.

References